Decoiler

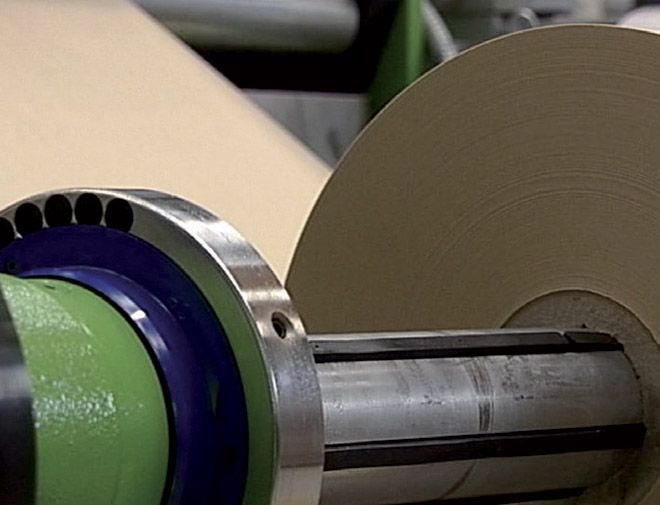

The decoiler unwinds the coil progressively without tearing the material.

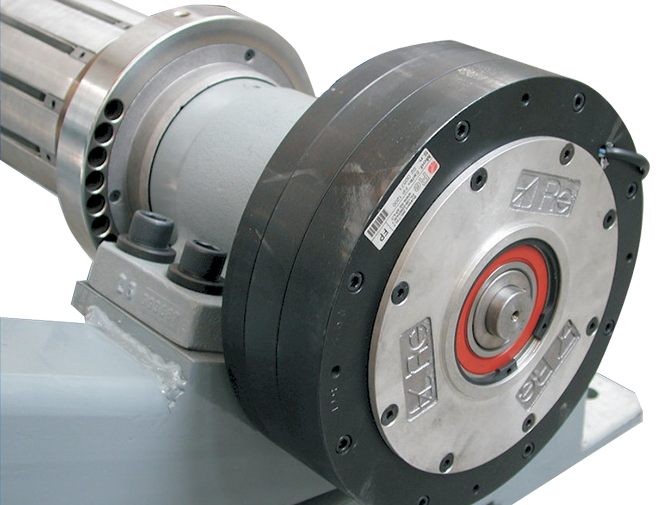

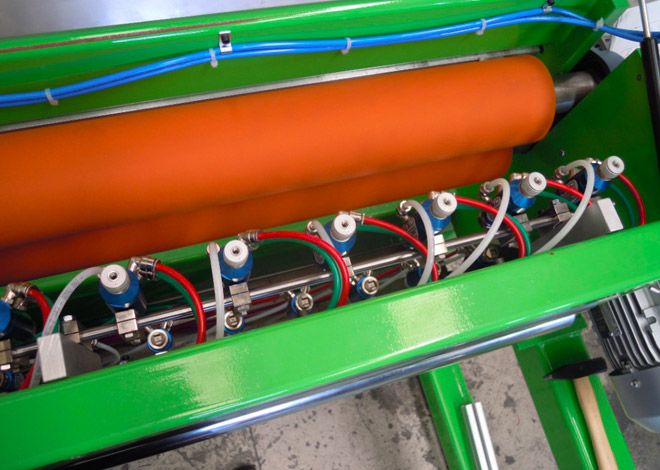

The coil is supported by an expansion shaft which is inserted into the core.

The shaft is driven by a variable speed motor to unwind the coil as required according to the speed, step and cycle rate of the electronic feeder on the press.

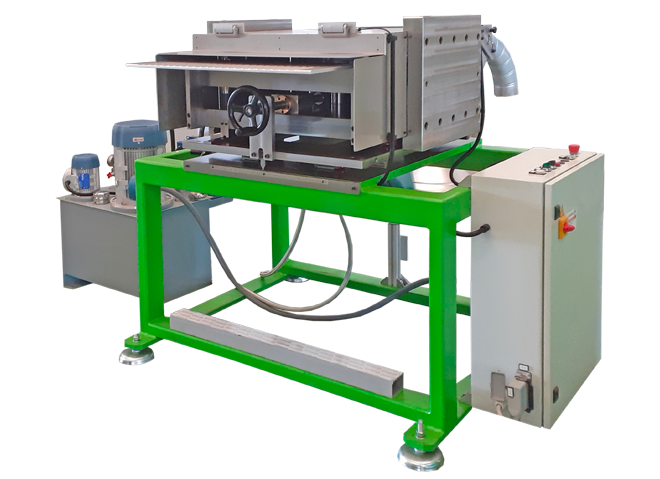

The decoiler also includes in case of need a lubricator for the aluminium strip with a stainless-steel basin to compensate, when required, insufficient lubrication on the pre-lubricated material, or also a new spray lubrication system (see also the detail in the list).

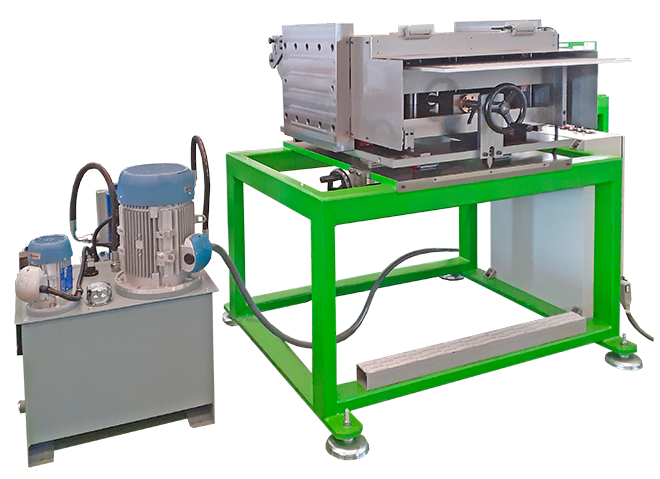

The QUALITY TOOLS Easydevo is the standard one decoiler for aluminium and paper lines products.

The QUALITY TOOLS Devolift is equipped with a fully automatic hydraulic coil lifting system that helps to lodge the coil.

The coil is supported by an expansion shaft which is inserted into the core.

The shaft is driven by a variable speed motor to unwind the coil as required according to the speed, step and cycle rate of the electronic feeder on the press.

The decoiler also includes in case of need a lubricator for the aluminium strip with a stainless-steel basin to compensate, when required, insufficient lubrication on the pre-lubricated material, or also a new spray lubrication system (see also the detail in the list).

The QUALITY TOOLS Easydevo is the standard one decoiler for aluminium and paper lines products.

The QUALITY TOOLS Devolift is equipped with a fully automatic hydraulic coil lifting system that helps to lodge the coil.